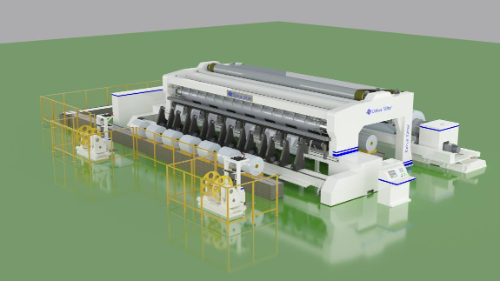

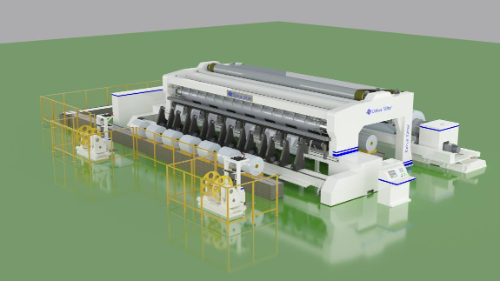

The production steps involved in manufacturing an

ultra-wide primary slitter can vary depending on the specific design and manufacturer. However, here is a general outline of the typical production process:

Design and Engineering: The first step is the design and engineering phase, where the requirements and specifications of the ultra-wide primary slitter are determined. This includes considerations such as the maximum width of the material to be slit, desired slitting precision, cutting speed, and other features.

Material Selection: The appropriate materials for constructing the slitter are selected based on factors like durability, strength, and corrosion resistance. Common materials used for the slitter components include high-quality steel, aluminum, or alloys.

Component Fabrication: The individual components of the slitter, such as the frame, shafts, blades, spacers, and tension control systems, are fabricated. This involves processes like cutting, machining, shaping, and welding. Precision and accuracy are crucial at this stage to ensure proper functionality of the slitter.

Blade Manufacturing: The slitter blades, also known as slitting knives or slitting discs, are manufactured separately. The blades are made from high-quality tool steel or other suitable materials, and they undergo processes such as cutting, grinding, heat treatment, and sharpening to achieve the required sharpness and durability.

Assembly: Once all the individual components and blades are ready, the assembly process begins. The components are assembled and connected to form the complete slitter unit. This includes mounting the blades onto the shafts, installing tension control systems, aligning the blades properly, and integrating any necessary control mechanisms.

Testing and Quality Control: The assembled slitter undergoes rigorous testing and quality control procedures to ensure its performance meets the desired specifications. This may involve running test cuts on sample materials, checking for proper blade alignment, measuring slitting accuracy, and evaluating overall functionality.

Finishing and Surface Treatment: Depending on the specific requirements and preferences, the slitter unit may undergo surface treatments such as coating or painting for protection against corrosion and wear. Additionally, any necessary finishing touches or adjustments are made to ensure optimal performance.

Packaging and Shipping: Once the slitter unit has passed all quality checks, it is prepared for packaging and shipping to the customer. Proper packaging is essential to protect the slitter during transportation and prevent any damage.

It's important to note that the production process may involve additional steps or variations depending on the specific design and customization requirements of the ultra-wide primary slitter. Manufacturers may have their own proprietary processes or variations to meet their unique specifications and standards.Meanwhile,An ultra-wide primary slitter is a specialized machine used in various industries for the purpose of slitting or cutting wide rolls of material into narrower widths. Here are the key functions and capabilities of an ultra-wide primary slitter:

Slitting Wide Rolls: The primary function of an ultra-wide primary slitter is to slit wide rolls of material into narrower widths. These materials can include films, papers, foils, laminates, non-woven fabrics, textiles, and more. The slitter can handle extremely wide rolls, typically ranging from several meters to over ten meters in width.

Precision Slitting: Ultra-wide primary slitters are designed to achieve precise and accurate slitting results. They have mechanisms for precise control of tension, alignment, and positioning of the material during the slitting process. This ensures consistent and accurate cutting of the material into the desired widths.

Multiple Slitting Configurations: Ultra-wide primary slitters offer flexibility in terms of slitting configurations. They can be equipped with multiple sets of slitting blades or knife holders, allowing for different slitting patterns and multiple cuts in a single pass. Common slitting configurations include razor slitting, shear slitting, crush slitting, and score slitting.

Rewinding: Some ultra-wide primary slitters are equipped with rewinding capabilities. After slitting, the narrower strips of material can be rewound into separate rolls or onto individual cores, making them ready for further processing or packaging.

Tension Control: Ultra-wide primary slitters incorporate tension control systems to maintain consistent tension on the material throughout the slitting process. Proper tension control ensures smooth and accurate slitting without damaging the material or causing defects.

Edge Trim Removal: In addition to slitting, the slitter may have the ability to remove edge trims or side waste from the wide roll of material. Edge trim removal systems help maintain the quality of the final slit rolls by eliminating excess material from the edges.

Speed and Productivity: Ultra-wide primary slitters are designed for high-speed and high-volume production. They can handle large rolls of material and achieve efficient slitting at high speeds, resulting in increased productivity and throughput.

Automation and Control: Modern ultra-wide primary slitters often feature advanced automation and control systems. These systems allow for easy setup, precise control of slitting parameters, real-time monitoring of production, and integration with other manufacturing processes.

Safety Features: Safety is an important consideration in slitting operations. Ultra-wide primary slitters are equipped with various safety features, such as emergency stop buttons, safety guards, and interlock systems to protect operators and prevent accidents during operation.

The functions of an ultra-wide primary slitter enable efficient and precise slitting of wide rolls of material, contributing to improved productivity, material utilization, and quality in industries such as packaging, printing, converting, textiles, and more.