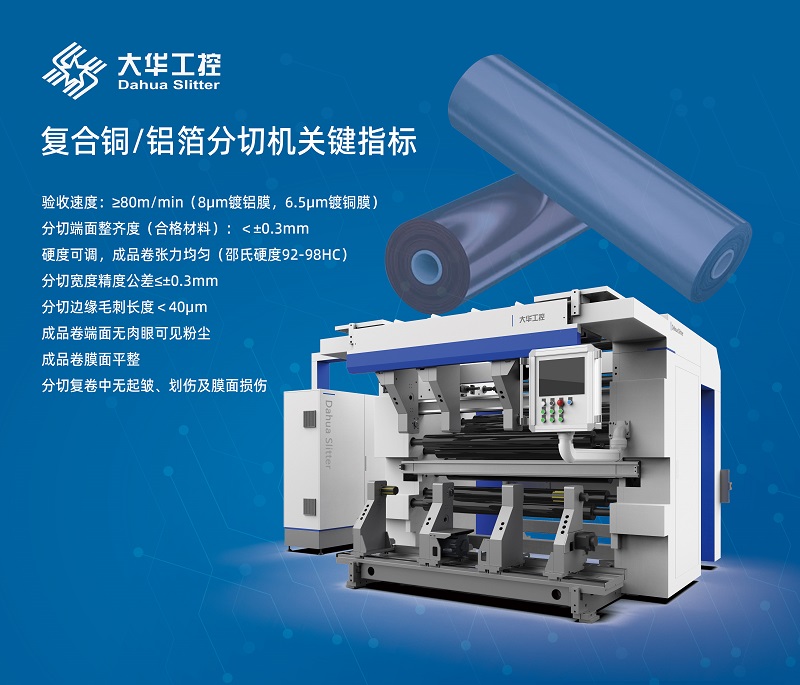

Composite Copper/Aluminum Foil (MC, MA) Slitter Key Indicators:

Acceptance Speed: ≥ 80 m/min (for 8μm aluminized film and 6.5μm copper-plated film)

Cutting Edge Neatness (for qualified materials): < ±0.3 mm

Adjustable Hardness, Uniform Tension of Finished Rolls: Shore hardness 92-98HC

Cutting Width Precision Tolerance: ≤ ±0.3 mm

Burr Length on Cutting Edges: < 40μm

No Visible Dust on the Edges of Finished Rolls

Smooth Surface of Finished Roll Film

No Wrinkles, Scratches, or Surface Damage During Slitting and Rewinding

This specialized composite copper/aluminum foil slitter has been completely upgraded. The new model features precise tension control and excellent slitting performance, effectively improving issues like burrs, wavy edges, and copper powder control during the slitting process of composite copper/aluminum foil materials. It has become the preferred choice for composite current collector material production enterprises. Interested parties, please contact: [email protected].