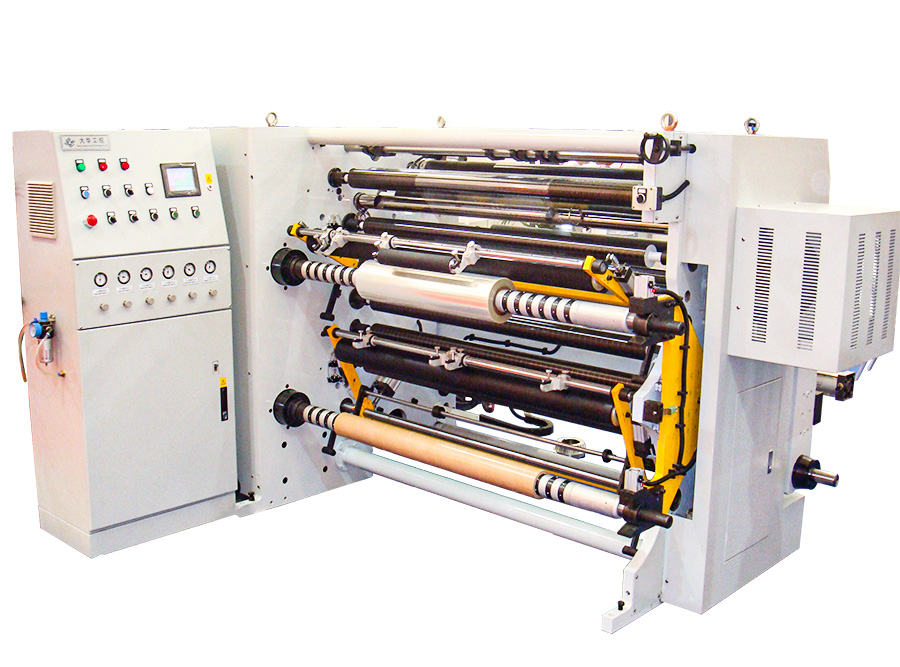

Modern slitter rewinders handle high-speed operations while maintaining precision and minimizing material waste through a combination of advanced technology, intelligent design, and efficient processes. Here's how they achieve this balance:

Advanced Tension Control Systems

Dynamic Tension Control: Modern machines use sensors and feedback systems to continuously monitor and adjust tension during both slitting and rewinding. This prevents stretching, wrinkles, or slackness in the material.

Zonal Tension Adjustments: The machine can manage tension differently across the width of the material, ensuring even handling for variable material properties.

High-Precision Cutting Mechanisms

Blade Technology: High-quality razor, shear, or crush cutting blades are engineered for durability and sharpness to ensure clean, accurate cuts even at high speeds.

Automatic Blade Positioning: Automated blade alignment minimizes errors and setup time, enhancing precision.

Intelligent Material Handling

Web Guiding Systems: These systems use optical sensors or cameras to track the material's position, automatically correcting alignment in real time to prevent edge irregularities.

Slit Edge Removal Systems: Integrated suction or edge-trim systems efficiently remove excess material, reducing waste.

Automation and Digital Controls

Programmable Logic Controllers (PLCs): Sophisticated software allows operators to pre-set material widths, tensions, and speeds, optimizing the process for each specific material.

Operator-Friendly Interfaces: Touchscreen controls enable precise adjustments and monitoring, ensuring consistent quality.

High-Speed Rewinding with Uniformity

Multiple Rewinding Techniques: Machines offer center winding, surface winding, or a combination, ensuring tight and consistent roll formation at high speeds.

Core Positioning Accuracy: Automated core alignment minimizes roll imperfections.

Minimizing Material Waste

Laser Scanning: Advanced machines use laser or optical systems to detect material defects before slitting, allowing for precise rejection of damaged areas.

Optimization Algorithms: Machines calculate the most efficient use of material rolls, reducing scrap while achieving the required dimensions.

Tension Synchronization: By avoiding over-tension or slack, the machine prevents material damage that could lead to waste.

Mechanical and Structural Innovations

Vibration Damping: Modern slitter rewinders are designed to minimize vibrations that could impact accuracy during high-speed operations.

High-Strength Components: Durable, lightweight materials like aluminum or composites reduce inertia and wear while maintaining structural integrity.

Integration of IoT and Smart Features

Real-Time Monitoring: IoT-enabled sensors provide live data on tension, speed, alignment, and material condition, allowing for proactive adjustments.

Predictive Maintenance: Machine learning algorithms analyze performance data to predict potential failures, reducing downtime and waste.

Energy-Efficient Systems

Regenerative Braking: Some machines use regenerative systems that recycle energy, reducing power consumption and operational costs.

Efficient Motor Systems: Servo and AC motors ensure smooth, responsive performance with minimal energy waste.